If you are searching for information on what are the differences between a displacement vs. centrifugal pump, in this article, we give you all the information you need to know about it. This allows you to know which is the most suitable for each type of industry and types of liquid.

At InoxMIM, we are manufacturers of pumps and agitators for various industries, and our almost two decades of experience are a guarantee of the good quality of all our machines.

Positive displacement pumps and centrifugal pumps are two different types of pumps used in industrial and water applications. Both are efficient and have their pros and cons, which it is convenient to know before deciding on one of them.

Next, we will make a description of the characteristics, uses, advantages and disadvantages between them. Please note that at InoxMIM we are experts in the field and, if you need it, we can provide you with personalized advice.

Positive displacement pumps

A positive displacement pump is a system that works by creating a constant volume of liquid that moves through the pump with each cycle. Positive displacement pumps are suitable for viscous and dense liquids.

Helical pumps are a type of positive displacement pump widely used in food applications. However, it should be noted that they are not suitable for pumping CIP solutions because they have a smaller flow range than a centrifuge and most cannot reach both working points.

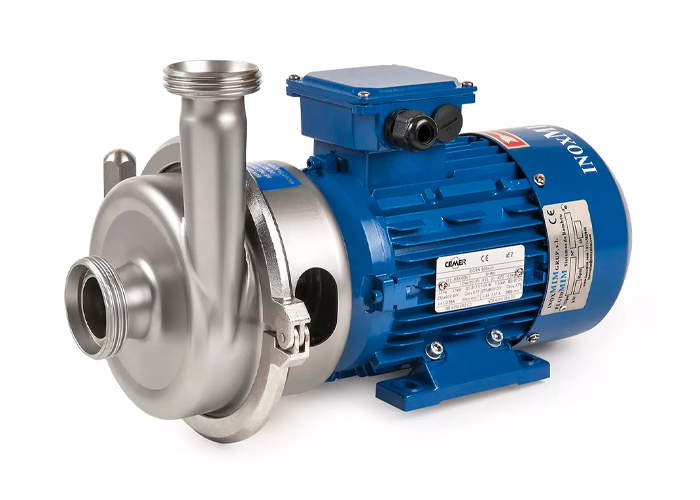

Centrifugal pumps

A centrifugal pump is a type of pump that uses centrifugal force to propel liquid through the pump. Centrifugal pumps are suitable for lightweight, particle-free liquids and are commonly used in water circulation and irrigation system applications. They can also be used in multiple industrial applications, for non-viscous products and for pumping purified water in pharmacies, for example.

This type of pump is the most used because they are economical, have a high flow and excellent pressure, in addition to few spare parts.

Helical positive displacement pumps or centrifugal pumps: which one to choose?

Given the need for a pump of these types, it is important to take several elements into account. Fundamentally, it depends on the following factors:

It is of utmost importance to consider these elements and choose the right pump to ensure efficient and reliable performance.

Other types of industrial pumps that can be found in the InoxMIM catalogue

In addition to positive displacement pumps and centrifugal pumps, at InoxMIM we design and manufacture other types of industrial pumps, such as:

In addition to these, at InoxMIM, we also manufacture pumps of other types. Each of them is available in different models and sizes, to adapt to the specific needs of each client.

We are also manufacturers of agitation systems

In addition to pumps of different types for industrial use, in our catalogue you will also find agitation and mixing equipment, to guarantee the mixing process. Some equipment of this type that we manufacture are:

Contact InoxMIM to find the pump that best fits the needs of your industry

At InoxMIM, we offer 100% personalized attention and technical advice for the development of projects of different sizes in different industries. If you have doubts or queries about our machines, we invite you to contact our sales team, who can provide you with all the information and attention you deserve, without any commitment.