Types of centrifugal pumps in our range

InoxMIM has been designing and manufacturing pumping and mixing systems since 1997. Through our FluidMIM division we supply equipment for transfer, dosing and recirculation across food & beverage, cosmetics, pharmaceuticals, chemicals and oenology.

Every model is sized from your process data—flow rate, total head (TDH), viscosity, temperature, NPSHa and chemical compatibility—to guarantee hydraulic performance, hygienic compliance and mechanical reliability.

Design principles we apply when engineering a centrifugal pump

Content table

Selected centrifugal pumps from our catalogue

A centrifugal pump converts the motor’s mechanical energy into kinetic energy and pressure via an impeller rotating inside a volute casing. Fluid enters at the impeller eye (low-pressure zone), gains tangential velocity, and is converted to differential head as it discharges through the volute.

This is the most widely used pump family in plants because it delivers high hydraulic efficiency, smooth, pulse-free flow, low maintenance and a competitive total cost of ownership.

FL20C Single centrifugal pump

- Click this link to view the FL20C single centrifugal pump product datasheet.

- Compact and efficient: monobloc design with a small footprint delivering flows up to 12 m³/h for the transfer of low-viscosity fluids.

- Materials and construction: industrial finish; wetted parts in AISI 316 stainless steel with a Ø90 mm semi-open impeller.

- Performance and ports: motors 0.37 kW (3,000 rpm) or 0.25 kW (1,500 rpm); 1″ suction / ¾″ discharge GAS threads.

- Applications and options: ideal for water, oils, glycols and wine; available with DIN 11851, CLAMP, SMS connections, motor shroud, and baseplate or trolley mounting.

FL30CI Centrifugal pump

- Click this link to view the FL30CI industrial centrifugal pump product datasheet.

- Build and finish: casing, impeller and shaft in AISI 316 with lantern in AISI 304; supplied in industrial or hygienic finish with hygienic mechanical seal.

- Hydraulics and design: open impeller (semi-open optional), 3,000 rpm, ports ASP/IMP DN100/DN65 or DN80/DN65; performance curves for multiple impeller diameters enable accurate duty-point selection.

- Connections and options: GAS / DIN 11851 as standard; on request DIN 2576 flange, CLAMP, SMS, RJT; optional baseplate or trolley and motor shroud.

- Applications and maintenance: designed for transfer duties in food, chemical and oenological processes; low part count simplifies maintenance and reduces downtime.

FL50CI Centrifugal pump

- Click this link to view the FL50CI food-grade centrifugal pump product datasheet.

- Hygienic/food: engineered for food, pharmaceutical and cosmetics processes with a high level of hygienic design; features an open impeller and hygienic mechanical seal.

- Materials and finish: wetted parts in AISI 316; structure (lantern/shroud/tripod) in AISI 304; available in food/sanitary finishes.

- Connections and options: DIN 11851 as standard; on request DIN 11861, GAS, CLAMP, SMS, RJT; mountable on baseplate or trolley.

- Performance and serviceability: performance curves with Ø90–140 impellers and 0.55–2.2 kW motors (reference flows up to ~25 m³/h); simplified construction for easy upkeep.

FLUID Centrifugal pump

- Click this link to view the FLUID hygienic centrifugal pump product datasheet.

Sanitary design and materials: wetted parts in AISI 316L, structure in AISI 304L; CLAMP and DIN 11851 connections; CIP/SIP-ready and EHEDG-compliant; optional sanitary finish Ra < 0.5 μm.

High hydraulic efficiency: high-performance impeller developed using computational design; flows up to 100 m³/h; reduced NPSHr to minimise cavitation and geometry that allows soft solid handling without product damage.

Sealing and configurations: mechanical seal C/I/EPDM, with EHEDG hygienic or double seal with thermosiphon available; broad connection range (DIN 11861, GAS, CLAMP, SMS, RJT) and options such as drain or heated casing.

Plant integration: IEC motors (B5/B3), VFD-ready, ATEX versions, and baseplate/trolley solutions with a low part count for rapid maintenance.

FL80CAI Self-Priming centrifugal pump

- Click this link to view the FL80CAI self-priming centrifugal pump product datasheet.

- Hygienic self-priming: designed for transfer in food, chemical and oenological duties where flooded suction is not available; supplied in food/industrial finishes with a hygienic seal.

- Construction and connections: semi-open impeller (open optional), simplified component set; GAS / DIN 11851 standard, with DIN 11861, CLAMP, SMS, RJT on request; baseplate or trolley options.

- Self-priming performance: at 2,900 rpm with ports ASP/IMP DN65/DN50 or DN50/DN50, achieves 4 m lift in 2–3 min (see curves by impeller size and motor power).

- Materials and sealing: lantern in AISI 304; casing/impeller/shaft/pipework in AISI 316; mechanical seals with graphite/silicon pairs and elastomers NBR/Viton/EPDM; IP55 50 Hz motor.

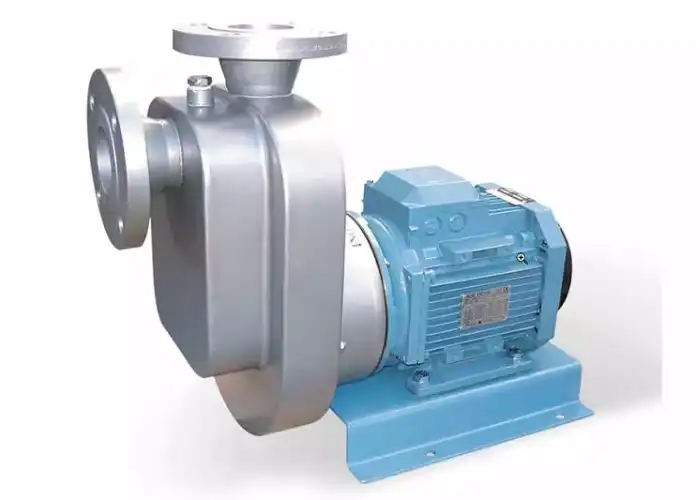

FL90CAI Industrial self-priming centrifugal pump

- Click this link to view the FL90CAI industrial self-priming centrifugal pump product datasheet.

- Self-priming for hygienic service: designed for transfer in food, chemical and oenological processes without flooded suction; food/industrial finish, semi-open impeller, hygienic seal and low part count.

- Self-priming and operation: at 2,900 rpm with ports ASP/IMP DN65/DN50 or DN50/DN50, achieves 4 m lift in 2–3 min; performance curves available for Ø130–Ø185 impellers and 1.5–5.5 kW motors.

- Materials and sealing: lantern in AISI 304; wetted parts (casing, impeller, shaft, pipework) in AISI 316; mechanical seals with graphite/tungsten/stainless pairs and NBR, nitrile or Viton elastomers; IP55 50 Hz motor (220–380 / 380–690 V).

- Connections and options: GAS / DIN 11851 standard; on request DIN 2576 flange, CLAMP, SMS, RJT; options include open impeller, baseplate or trolley, double mechanical seal with thermosiphon, and control panel.

Related articles:

Helicoidal-turbine centrifugal pumps (FL–CH)

FL–CH pumps use an open helicoidal impeller combining axial intake with centrifugal discharge. This geometry delivers a continuous, very low-shear flow and allows soft solids and aerated liquids to pass without clogging or hydraulic shock. The outcome is a stable flow that does not damage the product, even when it contains pieces, short fibres or foam.

When should you choose an FL–CH?

Operating advantages

Recommended uses

InoxMIM Catalogue

What are the technical advantages of InoxMIM centrifugal pumps?

Centrifugal pumps in the FluidMIM division are engineered with AISI 316L wetted parts and sanitary finishes on hygienic models, ensuring corrosion resistance, effective cleanability and compatibility with sensitive formulations. Impeller and volute hydraulics are optimised to extract maximum performance for the installed power, lowering NPSHr, mitigating cavitation and reducing energy consumption in continuous duty. The full range integrates with CIP/SIP routines and can be supplied with single or double mechanical seals—with thermosiphon systems where required—plus ATEX, FDA and EHEDG options on hygienic variants.

Mechanically, the pumps use a modular architecture to accelerate maintenance: standardised sleeves, seals, bearings and lanterns reduce spares inventory and downtime. In parallel, application-led customisation—by fluid viscosity, abrasiveness, pH and temperature, as well as sector regulations—allows precise selection of connections (DIN/CLAMP/flanged), impeller geometry and seal configuration for each installation. For a breakdown by families and variants, see the centrifugal pump manufacturer section.

In which industrial applications do centrifugal pumps fit best?

Centrifugal pumps FAQs

Please do not hesitate to contact our sales department

To request information or resolve doubts about any of our equipment or solutions, do not hesitate to fill in the following form with your contact details and you will receive news from one of our sales technicians in a short space of time.