Basic concepts about industrial pumps

Pumps are fundamental devices in a wide variety of industries, from water treatment to pharmaceutical and food manufacturing.

Their ability to move liquids from one place to another makes them an essential pillar for any industrial process that requires fluid handling.

In this post, we will explore two main types of pumps used in the industry: centrifugal pumps and positive displacement pumps. Each has its specific characteristics, advantages, and applications, so it is crucial to understand their differences to choose the most suitable option according to the specific needs of each process.

Pumps are indispensable for the efficiency and operability of many systems and are also significant for maintaining safety and integrity in processes involving chemicals, food, and pharmaceuticals. Understanding how they work and how they differ will help us better comprehend how to optimize the use of these vital pieces of equipment in our operations.

Next, we will detail the fundamental characteristics of centrifugal and positive displacement pumps, highlighting how their technical peculiarities adapt to different industrial environments and tasks.

This will not only allow us to understand their operation but also how InoxMIM, through its experience and specialization, can provide pumping solutions that meet the specific requirements of each customer.

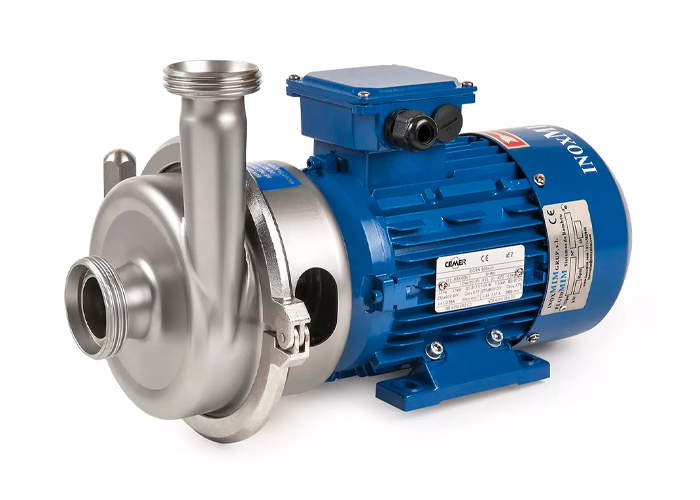

What are industrial centrifugal pumps?

InoxMIM offers a variety of centrifugal pumps designed to meet the specific needs of different industrial applications:

Each type of centrifugal pump from InoxMIM is manufactured with high-quality materials, such as AISI 316L stainless steel for parts in contact with the product and AISI 304L for other external parts, ensuring great durability and corrosion resistance.

Additionally, they offer customization options such as different types of mechanical seals, motor configurations, and connections to adapt to any industrial process.

Related articles:

What are positive displacement pumps?

Positive displacement pumps are essential equipment in the industry due to their ability to handle high-viscosity fluids, offering a constant flow regardless of the system pressure.

This type of pump operates by trapping a fixed amount of fluid and forcing it into the discharge section, resulting in a continuous and homogeneous flow.

These pumps are ideal for applications that require precise fluid handling, such as chemical dosing or processes where materials should not be excessively agitated. They are especially useful for pumping viscous, abrasive, or shear-sensitive fluids, such as processed foods, chemical pastes, and organic materials in water treatment.

Centrifugal Pumps vs. Positive Displacement Pumps

The choice between a centrifugal pump and a positive displacement pump depends on several factors related to the specific process, the nature of the fluid to be handled, and the requirements of the system. Here, we detail the key differences between these two types of pumps to help you decide which one is most suitable for your application.

How to choose between a centrifugal pump and a positive displacement pump

The proper selection of a pump for a specific industrial application can have a significant impact on process efficiency and cost. Here are some key factors to consider when making an informed decision between centrifugal pumps and positive displacement pumps:

What do we offer from InoxMIM?

InoxMIM, with its extensive experience in designing and manufacturing pumping solutions, offers not only high-quality products but also comprehensive services that include technical advice and equipment customization. Through its specialized department, AGITMIM, InoxMIM assists clients in selecting the perfect pump tailored to their needs.

With InoxMIM’s support, customers acquire an advanced centrifugal pump designed to optimize performance and reduce downtime, ensuring continuous and efficient operation in equal measure. If you need to resolve doubts or request a detailed quote, just take a few seconds to fill out your information in the following contact form. It’s that simple!

Contact us

We are here for your companyWe are here to helpWe are here to provide

We are here to help