Our catalog of industrial centrifugal pumps

In InoxMIM we are a leading company in the development and manufacture of innovative industrial machinery, with 25 years of experience. For this reason, there are many industries that trust us when it comes to buy a centrifugal pump to optimize your production processes.

Centrifugal pumps are a type of hydraulic pump used to transform the mechanical energy of the impeller with which it is driven into hydraulic energy. Generally, they are used to make water currents flow, as well as for the operation of liquids, which is why they are widely required in various production processes in different industries, being the chemical, cosmetics and food industries, the main users of this type of equipment.

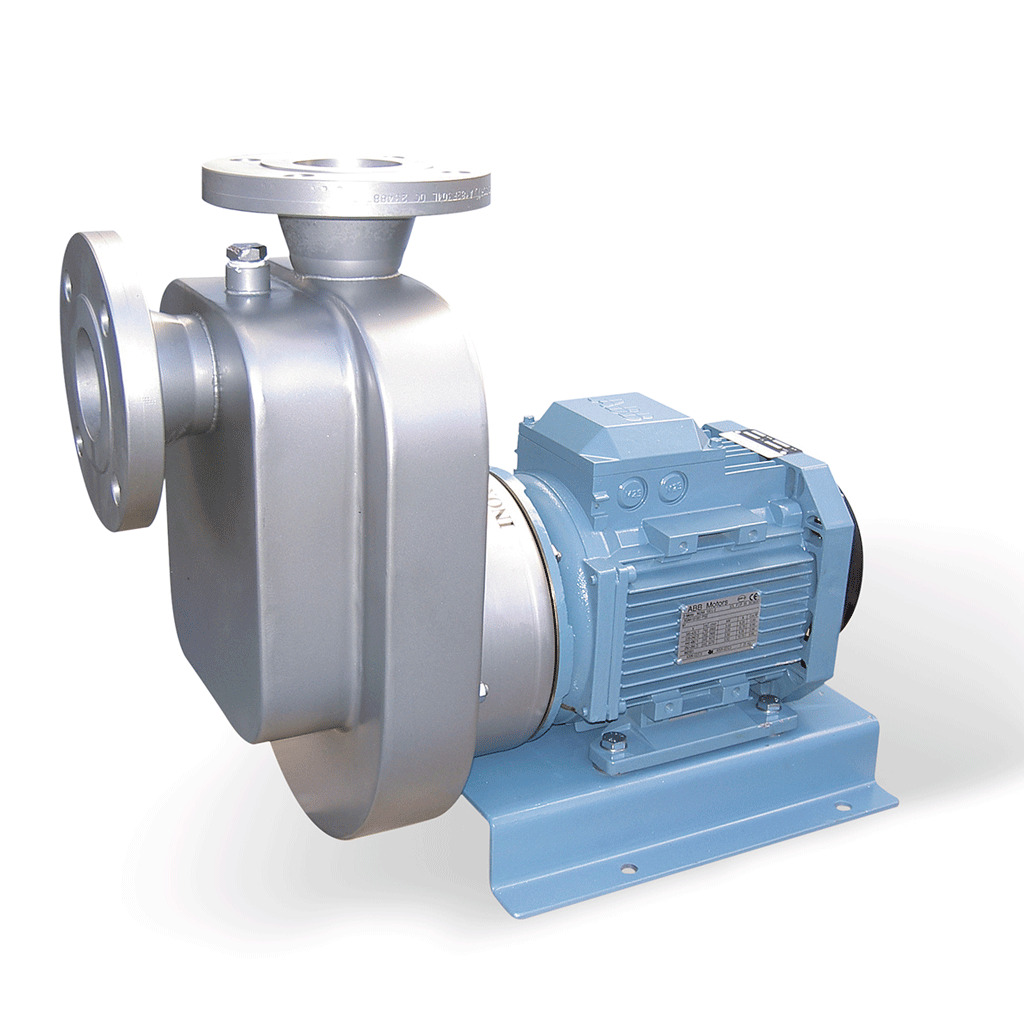

Centrifugal pumps

FluidMIM centrifugal pumps: reliability, performance and hygienic design

The principle of operation of a centrifugal pump is based on the transformation of the mechanical energy of the motor into the kinetic energy of the fluid. transformation of the mechanical energy of the motor into the kinetic energy of the fluid, through the rotation of an impeller designed to optimize the hydraulic flow.through the rotation of an impeller designed to optimize the hydraulic flow. This design allows to maintain constant and stable flow rates, reducing pulsations and vibrations.reducing pulsations and vibrations, with reduced energy consumption. reduced energy consumption compared to positive displacement pumps.

The centrifugal pumps of the FluidMIM centrifugal pumps are characterized by their high hydraulic efficiencytheir simplicity of maintenance and their modularityThe modularity of these pumps allows the equipment to be configured according to the specific requirements of each process. Thanks to optimized impeller geometry and precise machining, these pumps offer minimum cavitation level (reduced NPSHr) y hydraulic efficiencies in excess of 70 %, even under varying flow conditions.even under varying flow and pressure conditions.

InoxMIM centrifugal pump models

The following are the main models of the range FluidMIMrange, designed and manufactured by InoxMIM for high performance industrial applications.

Transfer of clean or slightly viscous liquids

Ideal for transferring transfer of food, cosmetic or chemical fluids with low viscosity, the InoxMIM centrifugal pumpsInoxMIM centrifugal pumps guarantee a constant and pulsation-free constant flow without pulsationmaintaining product integrity.

They are used to move liquids between tanks, feed intermediate tanks or transfer product to packaging or pasteurization lines.

Your high-performance impeller and its low NPSHr ensure stable operation even in installations with long pipe lengths or moderate head losses.

Feeding and recirculation in process lines

Centrifugal pumps are essential for maintaining the recirculation flow in mixers, homogenizers, reactors and heating or cooling systems..

Thanks to their robust and balanced design, FluidMIM pumps offer constant pressure and minimal vibration. constant pressure and minimal vibrationThese are critical factors for processes where precise flow control and thermal stability are required.

In environments with automated cleaning, its compatibility with CIP/SIP systems CIP/SIP systems allows direct integration into closed hygienic recirculation circuits..

CIP cleaning and recovery systems

The sanitary design of FluidMIM pumps allows their use as main pumps in cleaning-in-place (CIP) circuits. main pumps in cleaning-in-place (CIP) circuits..

These units provide the necessary flow and pressure to drive detergent or sanitizer solutions. propel detergent or sanitizing solutions through piping, valves and process equipment, ensuring effective cleaning without disassembly.

In addition, its chemical and thermal resistance allows them to work with caustic soda, nitric acid or hot water at high temperatures, without degradingwithout degradation of materials.

Some models, such as the FL53CI or the FL83CAIare also used in CIP fluid recovery and return systems, optimizing chemical and water consumption.optimizing chemical and water consumption.

Feed pumps for exchangers or reactors

In thermal transfer or thermal transfer or controlled reactioncentrifugal pumps act as feed or recirculation feed or recirculation elements within heat exchangers, reactors or evaporation systems.

Its stable operation and hydraulic precision allow it to maintain maintain constant flow rateswhich favors a uniform heat uniform thermal transmission and a homogeneous chemical reaction.

Models FL53CI, FL83CAI and FL93CAI FL53CI, FL83CAI and FL93CAI are frequently used in heat exchange heat exchange systems, mixing reactors and bioreactors, where reliability and cleanliness are essential.where reliability and cleanliness are essential.

Filling, filtration and heat transfer applications

FluidMIM centrifugal pumps are used as feed or discharge pumps. feed or discharge pumps in tangential filtration equipment, filter presses or microfiltration systems, where flow stability is key to process efficiency.

In automatic filling operations automatic fillingIn automatic filling operations, its ability to maintain constant pressure and absence of pulses reduces valve wear and avoids overfilling.

They are also used for recirculating fluids in heating, pasteurization or cooling systems, ensuring uniform heat transfer and optimum energy efficiency.ensuring uniform heat transfer and optimum energy efficiency.

Production processes in the food, chemical, cosmetic and pharmaceutical industries

The hygienic design and modularity of the InoxMIM pumps allow them to be installed in multifunctional production plantswhere process and cleanliness requirements are particularly demanding.

- In the food industryThey are used for the transport of milk, syrups, juices, sauces or concentrates, guaranteeing the safety of the product.

- In the cosmetic industryThey ensure gentle handling of creams, gels and emulsions, preserving their texture and stability.

- At chemical and pharmaceutical processesIn chemical and pharmaceutical processes, they stand out for their compatibility with corrosive or high purity fluids, as well as for their ability to operate under ATEX or GMP regulations.

Thanks to their robust construction, FluidMIM centrifugal pumps assure operational continuity, low life-cycle costs and maximum plant reliability, being an essential component in modern automated production lines.They are an essential component in modern, automated production lines.