InoxMIM: manufacturers of industrial production machines for different sectors

InoxMIM is a machine manufacturer made up of industrial engineers and technical specialists with a real passion for their work. In the company we have different departments dedicated to the manufacture of machinery for the food, cosmetic, pharmaceutical or chemical industry. Throughout our more than twenty years of history, we have specialized in the design and production of a complete range of centrifugal pumps and pumping systems, industrial agitators or complete product processing units, for these specific sectors.

Design of process equipment and customized production plants

As machine builders, it is important to explain that the design and development of custom units has been part of InoxMIM’s DNA since we started in this world more than twenty years ago. Throughout all this time, we have made and installed all types of mixing and pumping SKIDs for a wide variety of industrial applications, always with the aim of finding the best possible solution for each of our customers.

If you are thinking of buying any of our equipment, or just want to ask us a question, just contact our sales department. We will be happy to assist you and offer you a direct and personalized treatment. What exactly do you need?

Stirrers, counter-rotating Cosmetics plant

Complete reactors Cosmetic plant

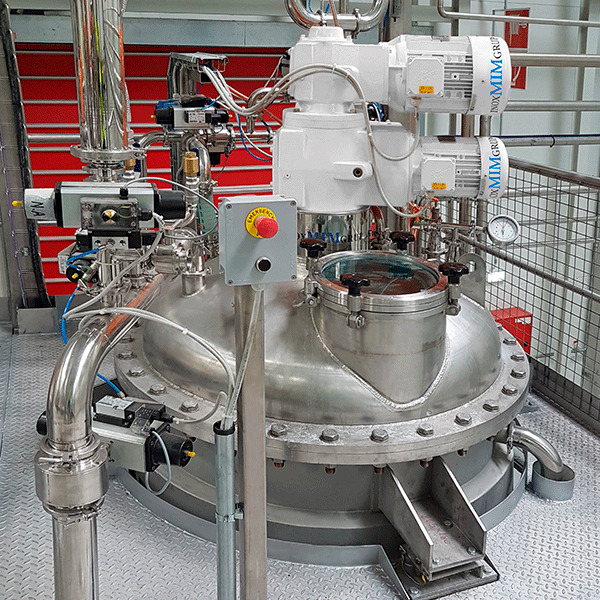

Bottom emulsifier with recirculation

Process equipment and machinery we can offer you

Apart from the design of custom processing plants, we have been embarking on the development of our pasteurization and heat treatment lines for the food industry for more than ten years now. On the other hand, we also started working on the manufacture of production units of cosmetic creams or sauces, until we reached the point where we are today.

We can offer and market to all our customers:

On the other hand, according to the needs of each client, special agitation equipment, lifting systems, integrated joint pumping and mixing solutions, filtration, and cleaning equipment are manufactured…

Complete reactors with counter-rotating agitation

Counter-rotating system for cosmetic creams

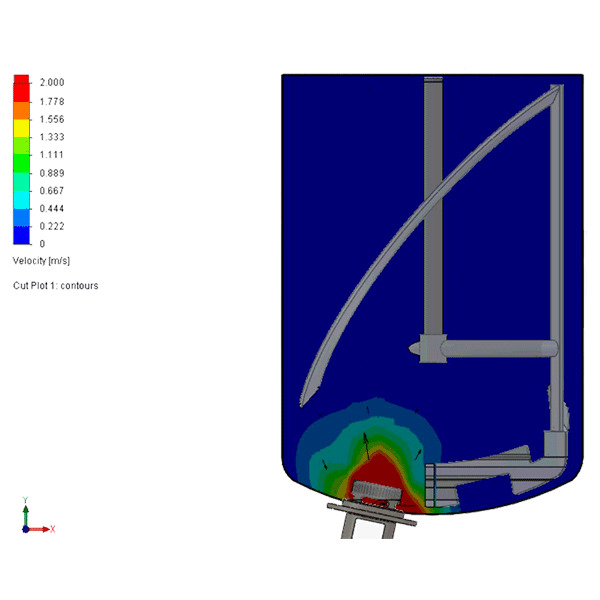

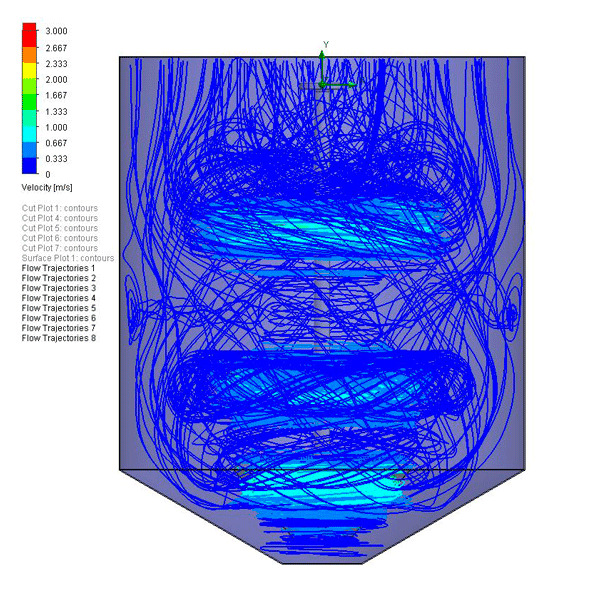

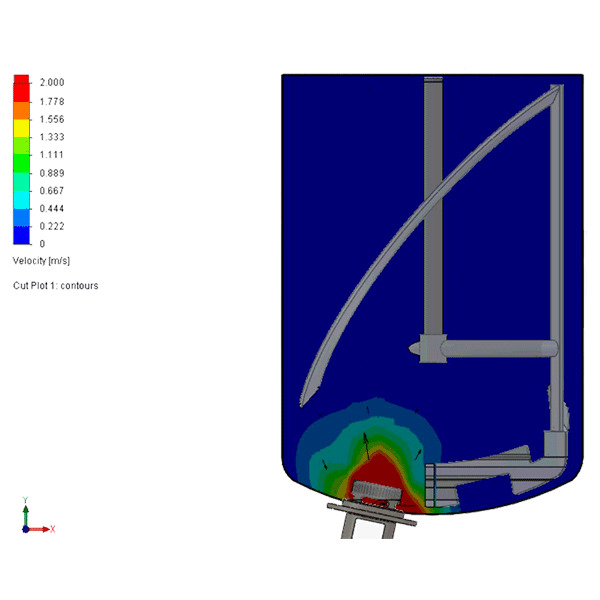

Since its inception, INOXMIM has offered direct attention and technical advice for the development of projects. Our engineering department works with state-of-the-art management systems and software through parametric and fluid simulation programs, guaranteeing the best solution.

Cip cleaning equipment for industry

Household cleaning product processing plants

Agitators for extraction

Agitation and reactors Chemical industry

Counter-rotating agitators Cosmetics plant

CIP cleaning equipment for industry

At InoxMIM, we also design and manufacture complete CIP (Clean in Place) cleaning equipment to carry out rigorous hygiene processes. These processes, within the food, cosmetic or chemical industry, roll on four very important factors to consider: the mechanical factor, time, temperature, and detergent. It is about finding the balance between all of them to achieve an effective cleaning of all the equipment, tools, and surfaces used for industrial production.

Within these sectors, two different types of dirt usually appear: organic, which is formed by the remains of fats and proteins; the mineral, composed of the precipitations of Mg, Ca or other elements. For its disposal, along with these CIP cleaning equipment, alkaline, acidic and disinfectant products are used. If you have doubts about this, do not hesitate to contact us so that we can study your needs carefully, until we find the best possible solution.