Factors to consider when choosing an industrial centrifugal pump

To correctly choose the pump model that best suits the needs of each customer, it is necessary to analyse a series of fundamental aspects before acquiring the product. Everything is important when selecting the best option, and once our technicians have the necessary data, they will offer you the centrifugal pump that best meets your application. In this regard, it is essential to know the following beforehand:

INOXMIM: specialists in the design and manufacture of industrial centrifugal pumps

The intended use of the centrifugal pump will be decisive in the final choice. The most common is for pumping water and non-corrosive liquids, but their range of applications is expansive.

They are also used to increase the pressure in water rings, use in construction, excessive accumulation in ponds and irrigation on farms, to name just a few of the most common.

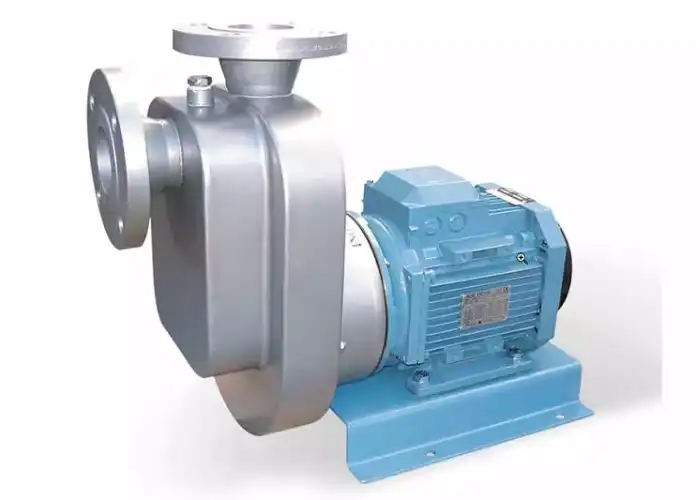

Through FLUIDMM, our exclusive department for the manufacture of industrial pumps, we develop a range of pumping equipment ranging from centrifugal pumps to positive displacement pumps with a wide range of applications in industry.

We adapt to the needs of our customers by customizing pumping equipment with special features, integrating pumping and mixing, cleaning and filtration equipment, etc.

We take care of choosing the perfect solution to ensure the highest possible cost-effectiveness. As a highlight and to show our wide range of solutions, we present two types of pumps: FL and food grade models.

FL family centrifugal pumps

Food centrifugal pumps

FLUID hygienic centrifugal pump: within the new FLUID pump range, this model has been designed to strictly comply with the EHEDG standard. Total guarantee of cleanability after SIP or CIP disinfection without the need for disassembly. The volume of flow it can provide is up to 100 cubic metres per hour, with high-performance and low consumption.